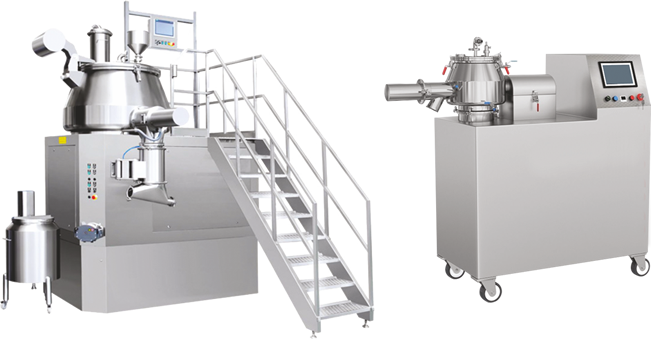

The parts of Neocorp’s rapid mixer granulator (RMG) are extremely responsive to the granulation process and are used for mixing, agitation, and shear mixing. The mass of the granules is mixed and broken up by the chopper and impeller. At the lowest portion of RMG, discharge points are connected horizontally. To eliminate purging air and trapped granules inside, the filter is installed with a vent air filter.

The chopper aids in breaking or lowering particle size, while the impeller is in charge of mixing the granules uniformly. The impeller and chopper typically run at low speed at startup. They are then run at a high speed to create the correct granule size after the production of the wet mass. After putting all of the supplied components into the rapid mixer granulator machine, dry mixing is carried out quickly.

Before compression, the rapid mixer granulators for pharma industry are essential for mixing the materials and creating granules. In a quick granulator, choppers and impellers are primarily in charge of wet granulation. Neocorp is regarded as one of the best RMG manufacturers in several industries, holding capabilities like high shear granulation, dry powder granulation, wet granulation, and wet mixing.

Two half-length blades and two full-length blades are placed on the impellers in our rapid mixer granulator machines. Designed so that the material is pushed by the full-length blades while being lifted by the half-length blades, breaking up the moist bulk into smaller pieces and granules.

Compared to impellers, a chopper contains very small, sharp blades that are intended to cut moist lumps of material into extremely minute pieces that are then combined by impellers. Our range of rapid mixer granulators comes with various accessories such as a steam jacketed bowl, temperature sensor (If jacketed is selected), flameproof construction, wet sizing mill, and variable frequency AC drive for impeller & chopper.

| Model / Size | RMG 2.5 | RMG 5 | RMG 10 | RMG 15 | RMG 25 |

| Gross Volume [in Litres.] | 2.5 | 5 | 10 | 15 | 25 |

| Working Volume [in Litres] | 2 | 4 | 8 | 12 | 20 |

| Impeller Motor [H.P.] | 2.5 | 2.0 | 2.0 | 2.0 | 3.0 |

| Impeller Motor [H.P.] | 0.50 | 0.50 | 0.75 | 0.75 | 1.0 |

| Model / Size | RMG 50 | RMG 100 | RMG 150 | RMG 200 | RMG 250 | RMG 300 | RMG 400 | RMG 600 | RMG 800 | RMG 1000 | RMG 1200 |

| Gross Volume [in Litres.] | 50 | 100 | 150 | 200 | 250 | 300 | 400 | 600 | 800 | 1000 | 1200 |

| Working Volume [in Litres] | 40 | 80 | 120 | 160 | 200 | 240 | 320 | 480 | 640 | 800 | 960 |

| Impeller Motor [H.P.] | 7.5 | 10 | 15 | 25 | 30 | 35 | 40 | 50 | 60 | 75 | 100 |

| Impeller Motor [H.P.] | 2.0 | 3.0 | 0.75 | 5.0 | 5.0 | 5.0 | 7.5 | 10.5 | 12.5 | 15.0 | 20.0 |

A-7, 2 Floor, Safal Profitaire, Corporate Road, Nr. AUDA Garden, Prahaladnagar, Satellite, Ahmedabad-380015. Gujarat (INDIA)

Neocorp. © 2024 | All Rights Reserved